Advanced model Slider type LGXS

High Precision Accuracy grades C5, High Durability , Clean specification as a standard feature.

|

Advanced model LGXS Higher efficiency, accuracy, and reliability from ground ball screw. Ideal for base axis of multi-axis configuration. -Maximum payload:2kg to 160kg |

LGXS Supported motor manufacturers

*For the supported models and capacities, refer to the detailed page of each model in this catalog.

[Servo motor]

Yasukawa Electric, Mitsubishi Electric, KEYENCE, OMRON, Panasonic

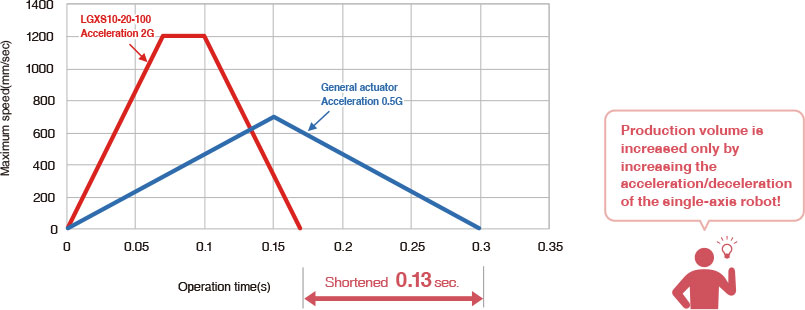

with Maximum acceleration of 2G

KAIZEN process of productivity starts from single axis robots.

LGXS series were added to Robonity line to meet the increasing demand of productivity improvement.

Benefit of higher acceleration/deceleration:

Reduction of operation time in the same lot = increased production volume in the same time

What’s new with advanced LGXS series?

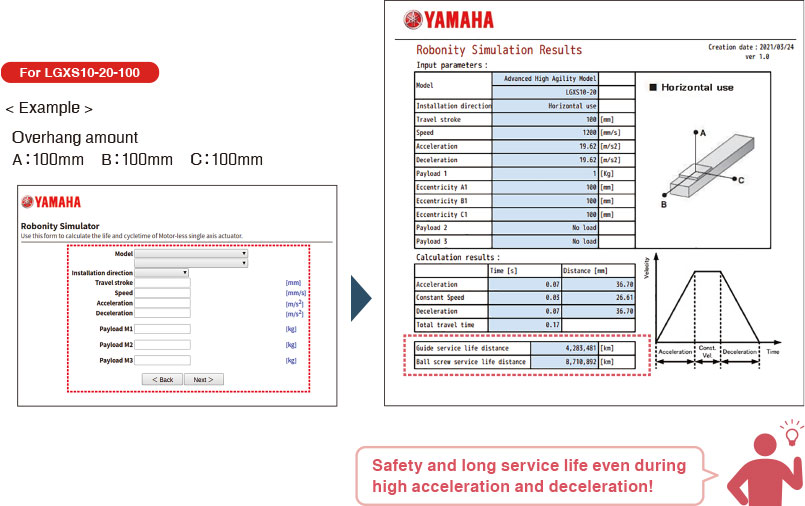

It is a ground ball screw for higher precision, longer life, and better dynamic characteristics.

Impact of higher G acceleration/deceleration

Service life when the payload is 1kg.

Improvement effect

<Example>

Movement stroke is 100 mm. Payload is 1kg. Robot operates 8 times per cycle.

Daily operation hours are 8 hours. Robot operates for 20 days every month. Operating ratio is 100%.

The estimation is made under the above conditions.

| Work time | Robot operation time | Total time | Production volume per hour | Production volume per day | Production volume per month | |

| 0.5G | 8sec. | 0.3sec. | 10.4sec. | 346pcs. | 2768pcs. | 55360pcs. |

| 2.0G | 8sec. | 0.17sec. | 9.36sec. | 384pcs. | 3072pcs. | 61440pcs. |

As a result, there is a difference of about 6,000 pcs. (about 10%) in one month under exactly the same operating conditions.

A robot is a robot…. regardless of brand…isn’t it?

From Yamaha R&D

Yamaha's single-axis robots have excellent durability and long product service life. The “Robonity” series has been evolved further. By utilizing our accumulated know-how and the features of each component to the maximum extent, the products confidently meet various needs of our customers, such as low cost, productivity, space saving, and quality improvement.

Features

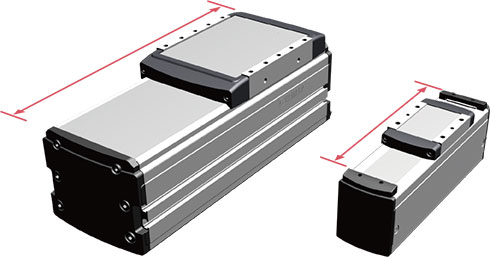

1. Shortest Overall Length

| The industry’ s shortest class is achieved for the total length in relation to the effective stroke. |  |

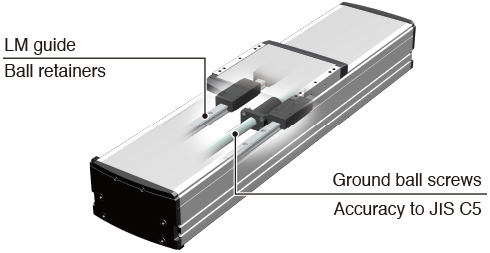

2. High Precision

| -Adopted ground ball screws Ball screw Remove Accuracy: Accuracy class C5 -Positioning Remove Accuracy repeatability: +/-5 μm |

|

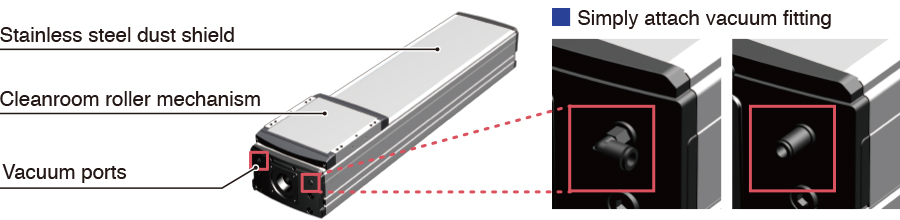

3. Cleanroom Ready Design

-Protective stainless dust shield

-Ports are ready for vacuum fittings

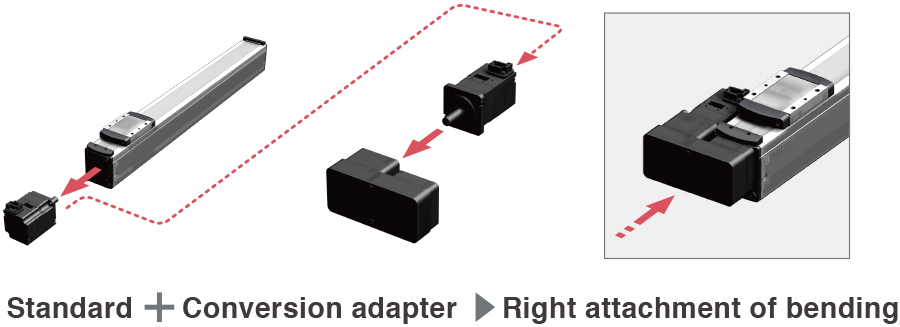

4. Motor orientation is changeable with optional conversion unit

Motor unit of standard straight type can be used for side-mount setup.

Specification

| Model | Adaptable motor (W) |

Repeatability (±mm)* | Deceleration mechanism |

Stroke (mm) | Maximum speed (or equivalent) (mm/sec)** |

Ball screw lead (mm) | Maximum payload (or equivalent) (kg)*** |

|

| Horizontal | Vertical | |||||||

| LGXS05 (635 KB) | 50 | ±0.005 | Ground ball screw φ12 (C5 class) |

50 to 800 (50 mm pitch) | 1333 666 333 |

20 10 5 |

5 8 13 |

2 4 8 |

| LGXS05L (667 KB) | 100 | 12 24 32 |

3 6 12 |

|||||

| LGXS07 (643 KB) | Ground ball screw φ15 (C5 class) |

50 to 1100 (50 mm pitch) | 1800 1200 600 300 |

30 20 10 5 |

10 25 45 85 |

2 4 8 16 |

||

| LGXS10 (740 KB) | 200 | 50 to 1250 (50 mm pitch) | 1800 1200 600 300 |

30 20 10 5 |

25 40 80 100 |

4 8 20 30 |

||

| LGXS12 (704 KB) | 400 | 35 50 95 115 |

8 15 25 45 |

|||||

| LGXS16 (752 KB) | 750 | Ground ball screw φ20 (C5 class) |

50 to 1450 (50 mm pitch) | 2400 1200 600 |

40 20 10 |

45 95 130 |

12 28 55 |

|

| LGXS20 (763 KB) | 65 130 160 |

15 35 65 |

||||||

| Model | Rated thrust (or equivalent) (N) | Maximum dimensions of cross section of main unit (mm) | Overall length (mm) | Degree of cleanliness**** | Intake air (Nℓ/min)***** | Using ambient temperature and humidity |

| LGXS05 (635 KB) | 41 69 138 |

W48xH65 | ST+131.5 | ISO CLASS 3 (ISO14644-1) or equivalent | 30 to 100 | 0 to 40℃, 35 to 80%RH (non-condensing) |

| LGXS05L (667 KB) | 84 169 339 |

ST+161.5 | ||||

| LGXS07 (643 KB) | 56 84 169 339 |

W70xH76.5 | ST+202 | 30 to 115 | ||

| LGXS10 (740 KB) | 113 170 341 683 |

W100xH99.5 | ST+177.5 | 30 to 90 | ||

| LGXS12 (704 KB) | 225 339 678 1360 |

W125xH10 | ST+211.5 | |||

| LGXS16 (752 KB) | 320 640 1280 |

W160xH130 | ST+242.5 | |||

| LGXS20 (763 KB) | W200xH140 | ST+288.5 |

*Positioning repeatability in one direction.

**When a moving distance is short and depending on an operation condition,

***The rated thrust and maximum transferable weight are values assuming the attached motor outputs the rated torque.

****When using in a clean environment, attach a suction air joint. The degree of cleanliness is the cleanliness level achieved when using at 1000 mm/sec or less.

*****The required suction amount will vary according to the operating conditions and operating environment.