Basic model Slider type LBAS

High Rigidity, Compact, Low Cost. Designed to accommodate motors from most leading manufacturers.

|

Basic model LBAS Newly designed integrated guide rail/frame structure. Improved moment load capacity in compact frame size. Designed to accommodate motors from most leading manufacturers. -Maximum payload:2kg to 100kg |

LBAS Supported motor manufacturers and standards

* For the supported models and capacities, refer to the detailed page of each model in this catalog.

[Servo motor]

Yasukawa Electric, Mitsubishi Electric, KEYENCE, OMRON, SANYO DENKI, TAMAGAWA SEIKI, DELTA ELECTRONICS, Panasonic, FANUC, Siemens AG, Rockwell Automation, Inc., Schneider Electric SA, KINGSERVO Hoof automation CO., LTD., Beckhoff Automation GmbH & Co. KG

[Stepping motor]

Oriental Motor

[NEMA standards]

NEMA17, NEMA23

Feature

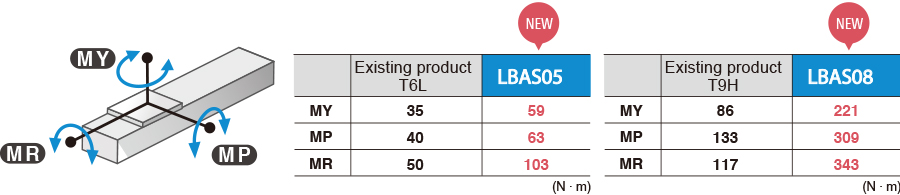

1. High Rigidity

Moment rigidity is increased approximately three times from current models.

2. High Precision

Straightness (running parallelism):+/-0.02/800 mm

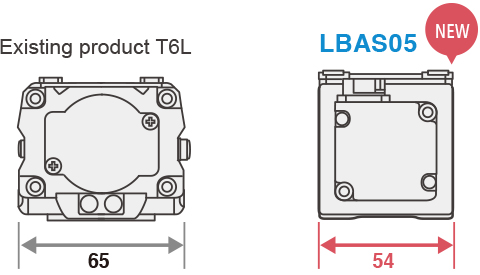

3. Compact

Frame width is reduced by approximately 20% from current models

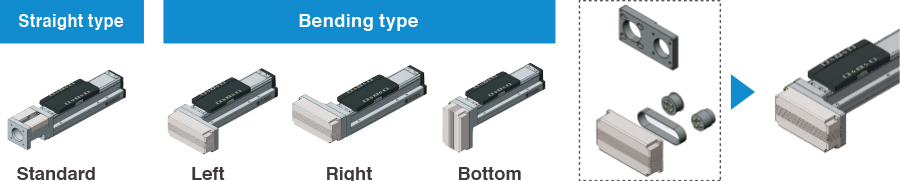

4. Motor attaching direction, Easily changeable with the special bending part

5. Installation process is simple and easy

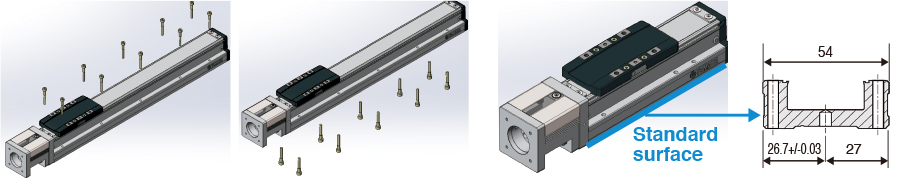

1.Mounting holes are accessible from top or bottom without disassembling actuator unit.

2.Standard surface on the side and dowel pin holes on the bottom.

6. Easy Maintenance

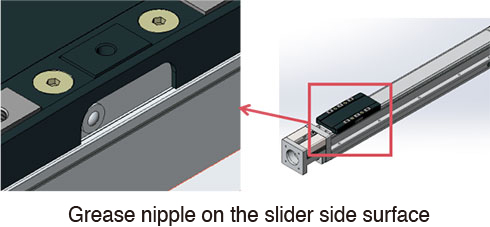

Moving parts can be lubricated from outside without opening actuator

Specifications

| Model | Adaptable motor (W) | Repeatability (±mm)* | Deceleration mechanism | Stroke (mm) | Maximum speed (or equivalent) (mm/sec)** | Ball screw lead (mm) |

| LBAS04 (726KB) | 50 | ±0.01 | Shifting position ball screw φ10 (C7 class) | 50~800 (50 mm pitch) |

800 400 |

12 6 |

| LBAS05 (713KB) | 100 | Shifting position ball screw φ12 (C7 class) | 1333 666 333 |

20 10 5 |

||

| LBAS08 (769KB) | 200 | Shifting position ball screw φ16 (C7 class) | 50~1100 (50 mm pitch) |

1200 600 300 |

20 10 5 |

|

| LBAS12 (907KB) | 200 | Shifting position ball screw φ16 (C7 class) | 50~1250 (50 mm pitch) |

1800 1200 600 300 |

32 20 10 5 |

| Model | Maximum payload (or equivalent) (kg)*** | Rated thrust (or equivalent) (N) | Maximum dimensions of cross section of main unit (mm) | Overall length (mm) | Using ambient temperature and humidity | |

| Horizontal | Vertical | |||||

| LBAS04 (726KB) | 12 20 |

2 5 |

71 141 |

W44 × H52 | ST+214 | 0 to 40°C, 35 to 80%RH (non-condensing) |

| LBAS05 (713KB) | 12 24 40 |

3 6 12 |

84 169 339 |

W54 × H60 | ST+220.5 | |

| LBAS08 (769 KB) | 40 80 100 |

8 20 30 |

174 341 683 |

W82 × H78 | ST+278 | |

| LBAS12 (907KB) | 20 40 80 100 |

3 8 20 30 |

105 170 341 683 |

W120 × H76 | ST+294 | |

*Positioning repeatability in one direction.

**When a moving distance is short and depending on an operation condition, it may not reach the maximum speed.

***The rated thrust and maximum transferable weight are values assuming the attached motor outputs the rated torque.