Basic model Rod type LBAR

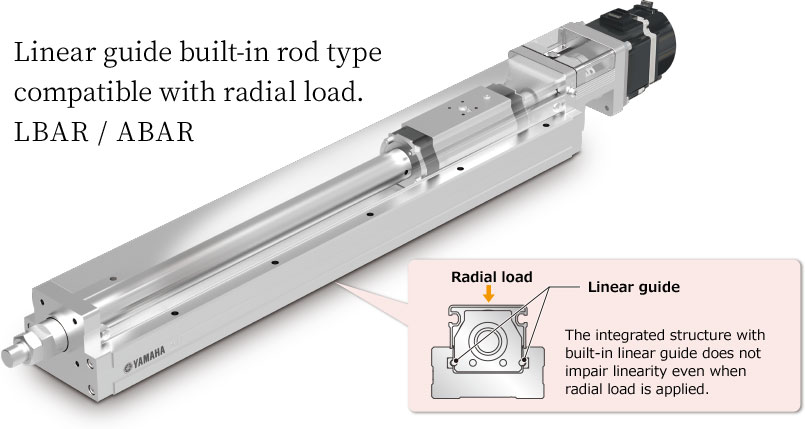

Linear guide built-in rod type compatible with radial load.

|

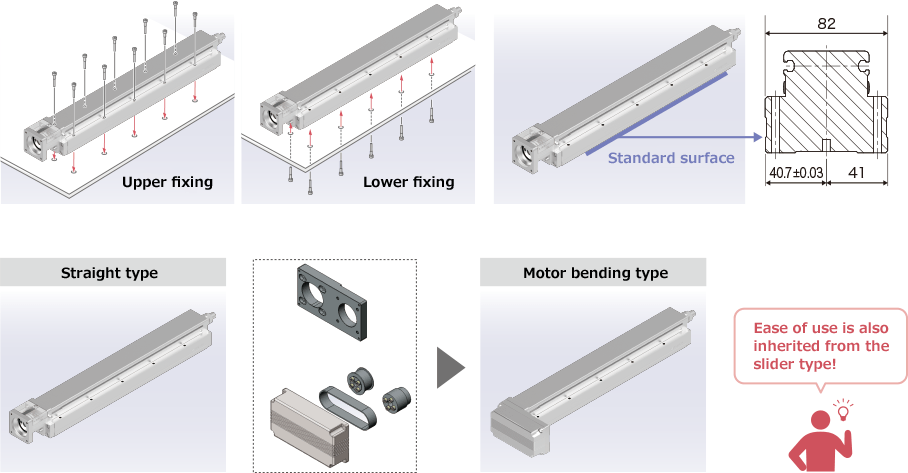

Basic model Rod type LBAR High rigidity structure that follows the slider type. -Maximum payload:Up to 80kg |

LBAS Supported motor manufacturers and standards

* For the supported models and capacities, refer to the detailed page of each model in this catalog.

[Servo motor]-Yasukawa Electric, Mitsubishi Electric, KEYENCE, OMRON, SANYO DENKI, TAMAGAWA SEIKI, DELTA ELECTRONICS, Panasonic, FANUC, Siemens AG, Rockwell Automation, Inc., Schneider Electric SA, KINGSERVO Hoof automation CO., LTD., Beckhoff Automation GmbH & Co. KG

[Stepping motor]-Oriental Motor

[NEMA standards]-NEMA17, NEMA23

Features

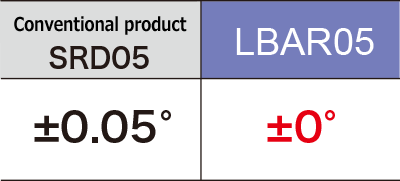

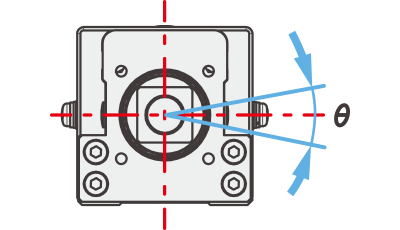

1. Rod non-rotation accuracy ±0°

The built-in linear guide suppresses rattling in the rotation direction.

The working accuracy of the tool attached to the tip of the rod is maintained.

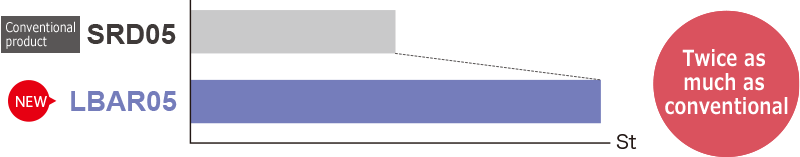

2. Compatible with a long stroke.

Compatible with a long stroke of up to 800 mm.

The corresponding stroke has doubled when compared to the conventional product with the same size.

This product can be used in a wide range of situations.

3. Easy installation and specification change

Specification

| Model | LBAR04 (973 KB) | LBAR05 (968 KB) | LBAR08 (1.0 MB) | ||||||

| Applicable motor (W) | 50 | 100 | 200 | ||||||

| Repeatability (mm)* | ±0.01 | ±0.01 | ±0.01 | ||||||

| Deceleration mechanism | Shifting position ball screw Ф10 (C7 class) | Shifting position ball screw Ф12 (C7 class) | Shifting position ball screw Ф16 (C7 class) | ||||||

| Stroke (mm) | 50 to 500 (50mm pitch) | 50 to 600 (50mm pitch) | 50 to 800 (50mm pitch) | ||||||

| Maximum speed (mm/sec)**/*** | 720 | 360 | 1200 | 600 | 300 | 1200 | 600 | 300 | |

| Ball screw lead (mm) | 12 | 6 | 20 | 10 | 5 | 20 | 10 | 5 | |

| Maximum payload (kg)*** | Horizontal | 15 | 25 | 15 | 25 | 50 | 30 | 60 | 80 |

| Vertical | 3 | 5 | 4 | 8 | 16 | 8 | 20 | 30 | |

| Max. pressing force (N) | 83 | 167 | 100 | 200 | 400 | 201 | 402 | 804 | |

| Rotating backlash | ±0° | ||||||||

| Maximum dimensions of cross section of main unit (mm) | W44×H46 | W54×H54.7 | W82×H73.5 | ||||||

| Overall length (mm) | Straight | ST+263 | ST+269.5 | ST+326 | |||||

| Bending | ST+245 | ST+249 | ST+312.5 | ||||||

| Using ambient temperature (℃) and humidity (%RH) | 0 to 40℃、35 to 80% RH(non-condensing) | ||||||||

| Servo motor | Yasukawa Electric、 KEYENCE、Mitsubishi Electric、OMRON、Panasonic、SANYO DENKI、TAMAGAWA SEIKI、DELTA ELECTRONICS、FANUC、Siemens、Schneider、Beckhoff、Allen-Bradley | Yasukawa Electric、 KEYENCE、Mitsubishi Electric、OMRON、Panasonic、SANYO DENKI、TAMAGAWA SEIKI、DELTA ELECTRONICS、FANUC、Kingservo、Siemens、Schneider、Beckhoff、Allen-Bradley | Yasukawa Electric、 KEYENCE、Mitsubishi Electric、OMRON、Panasonic、SANYO DENKI、TAMAGAWA SEIKI、DELTA ELECTRONICS、Siemens、Schneider、Kingservo | ||||||

| Stepping motor | Oriental Motor、NEMA standards | ||||||||

*Positioning repeatability in one direction.

**When a moving distance is short and depending on an operation condition, it may not reach the maximum speed. If the effective stroke exceeds 500 mm, the ball screw may resonate. (Critical speed) At this time, make the adjustment to decrease the speed while referring to the maximum speed shown in the table.

***The rated thrust and maximum transferable weight are values assuming the attached motor outputs the rated torque.