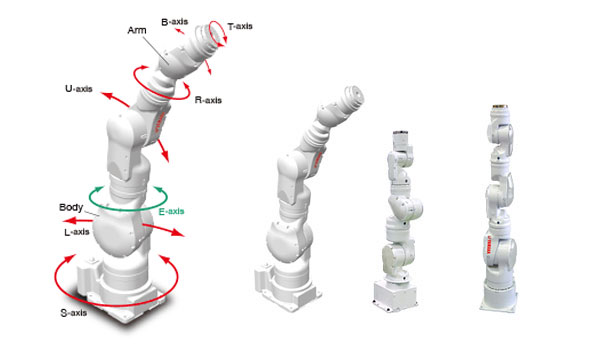

YA SERIES 7-axis

New Yamaha multi-axis articulated robots are available. Ideal for constructing compact cells, for moving or assembling small parts, and for performing inspection processes.

|

Reduce personnel, increase productivity |

Features

1. High-speed operation reduces cycle time

Thanks to a faster control frequency in the YAC100 controller and hand vibration suppression function, these robots achieve the highest operating speed in their class. From supply, assembly, inspection, and packing to palletization, all applications can enjoy shorter cycle time and improved productivity.

2. Workpieces with a high wrist load are also supported

With a wrist section that has the highest allowable moment of inertia in its class, these robots can support jobs involving a high wrist load, or simultaneous handling of multiple workpieces.

3. Dramatically reduce line setup time with a simulator

We provide software that lets you use 3D CAD data to construct a production facility in virtual space in a personal computer, and easily perform engineering tasks such creating programs and checking for robot interference. Teaching can be performed even before the actual production line is completed, dramatically reducing line startup time.

*Optional support

7-axis Free arm movement further boosts productivity.

4. Reduced space allows sophisticated system layouts

Since these robots can be installed close to workpieces or other equipment, you can reduce the space required for your production facility. By locating multiple robots close to each other, processing can be integrated and shortened.

5. "Elbow movement" unique to 7-axis models allows optimal posture to be maintained

7-axis U-type robots allow "elbow movement," changing only the elbow angle without affecting the position or posture of the tool. This permits operation to avoid nearby obstructions.

6. Access the workpiece from the opposite side or from below

Rotation of the seventh axis enables flexible movement with the same freedom of motion as a human arm, allowing the workpiece to be accessed from the opposite side or from below. This allows the robot to enter narrow locations that a person could not fit in, or to approach the workpiece in a way that avoids obstructions, giving you more freedom to design the layout for shorter cycle time and reduced space.

| Model | Application | Number of axis | Payload | Vertical Reach | Horizontal Reach |

| YA-U5F (348 KB) | Handling (General) | 7-Axis | 5 kg. | 1007 mm | 559 mm |

| YA-U10F (261 KB) | 10 kg. | 1203 mm | 720 mm | ||

| YA-U20F (335 KB) | 20 kg. | 1498 mm | 910 mm |